construction of jaw crusher

construction of jaw crusher

Mobile hard stone crusher (Jaw Crusher) Constmach Mobile Crushing Plant Mobile hard stone crusher (Jaw Crusher) - Werktuigen.com – Year of construction 2022 – Condition: New machine International

Learn More

To study the construction, operation and engineering utilities of “Blake jaw Crusher” . into coarse crushers, intermediate crushers and fine grinders.

Learn More

Crushed Stone. Crushed stone is a versatile product that can be used in a wide range of applications from construction to road building and even agriculture. Processing this material may include reducing its size with a crusher, sizing the crushed material with a screen and conveying the material into different stockpiles.

Learn More

The jaw chamber can be configured specifically for either processing construction demolition debris or quarrying applications. The machine has hydrostatic drive

Learn More

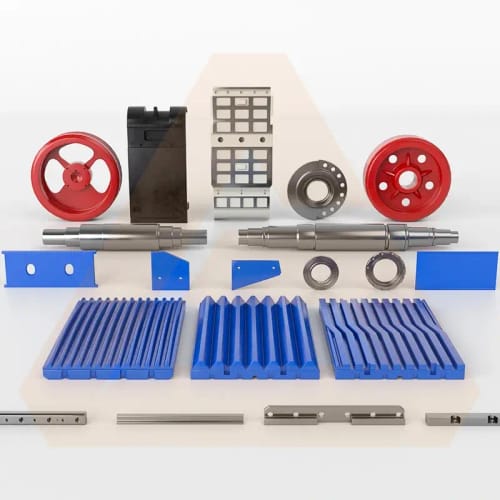

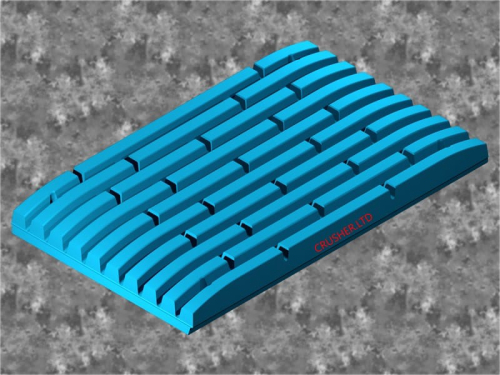

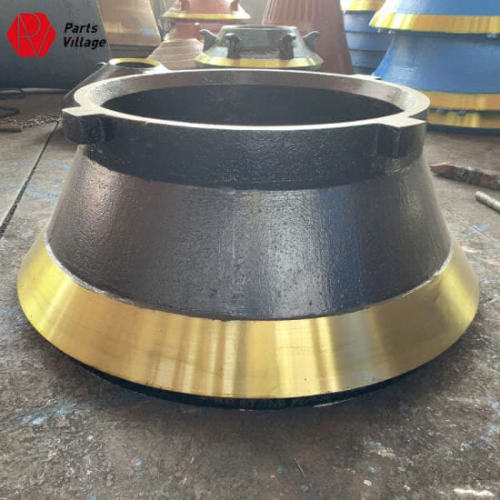

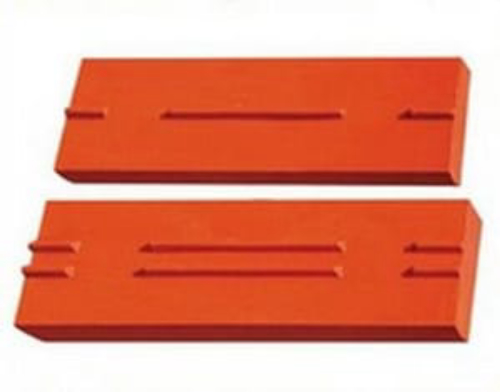

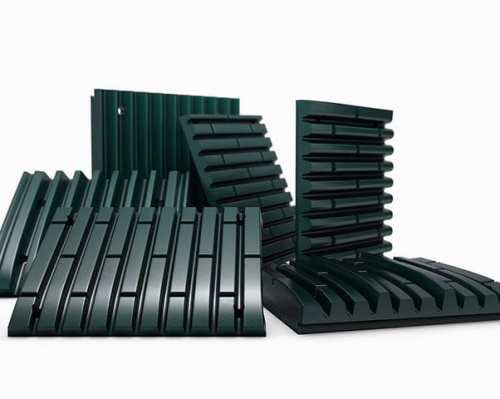

The jaws and side liners are made of cast manganese steel, ensuring a long service life. Frame. The frame's reinforced metal construction and heat treatment

Learn More

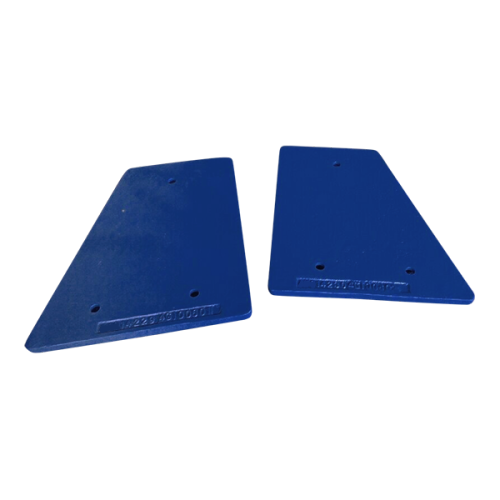

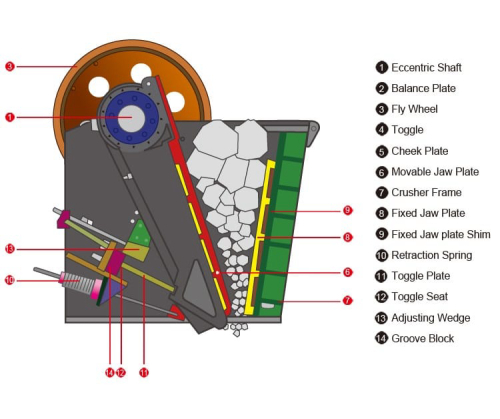

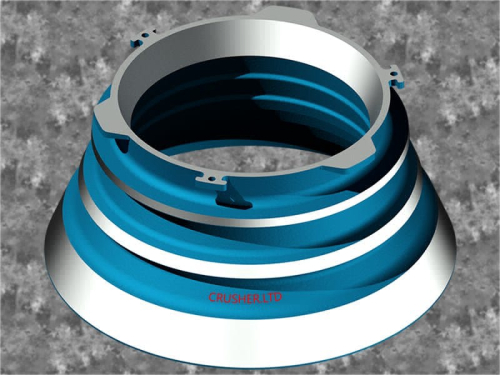

A jaw crusher consists essentially of two crushing plates, inclined to each other forming a horizontal opening by their lower borders. Material is crushed between a fixed and a movable plate by reciprocating pressure until the crushed product becomes small enough to pass through the gap between the crushing plates.

Learn More

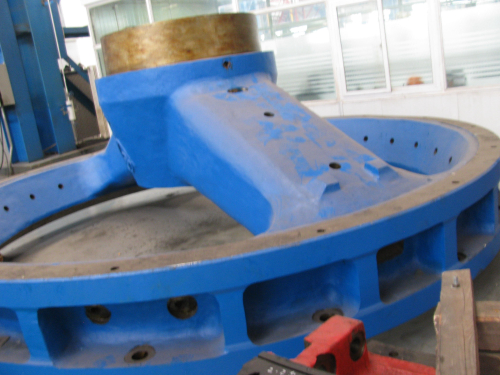

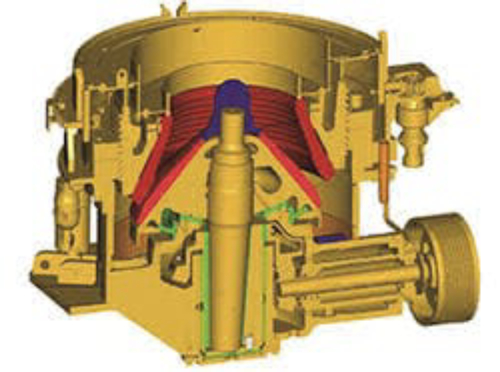

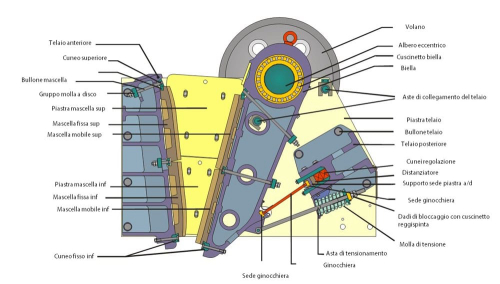

Construction detail and working of the crusher is as under. The main shaft of the crusher is journaled in the spider bearing and in the eccentric bearing assembly. The spider bearing fixes the position of the upper end of the main shaft. Eccentric bearing assembly with inner bushing can be replaced, or in some models turned, to adjust the stroke.

Learn More

Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing and reliable performance for increased operational productivity and profitability. Our diverse line of industry-leading jaw crushers offers producers the latest in jaw crushing technology

Learn More

As the first process of stone crushing line, Jaw Crusher always plays important role. This machine is possess of optimized crushing chamber, heavy eccentric shaft and high manganese steel jaw plate, which takes advantages of high efficiency, strong crushing ability and low investment costs. Applications: Mining, metallurgy, construction

Learn More

Calculation were carried out as per the required length,. shape, allowance and quantity needed to avoid waste of material. Jaw Crusher.

Learn More

OSTI.GOV Journal Article: Scaled-up apparatus for removing petroleum and solid bitumen from rock and for separating them from each other. [Design, construction, and testing of jaw crusher, extraction plant, deasphaltization plant, absorption chromatograph, and rectification plant]

Learn More

The Hot sale jaw crusher models are Jaw Crusher 250*400, Jaw Crusher 400*600, Jaw Crusher 600*900, etc. PE600*900 Co nstruction of Jaw Crusher Mobile Stone Crusher Line:

Learn More

5/6 · Metallurgical ContentJaw Crusher TerminologyJAW CRUSHERSDouble-Toggle Jaw CrushersSingle-toggle Jaw CrushersSizing Jaw CrushersForced Feed Jaw

Learn More

For example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top i.e. the opening), and each jaw will have a 54-inch width. If a

Learn More

Manufacturing Process Of Stone Crusher In India Brazil Crusher Manufacturers Mining Equipment Stone Crusher in Angola Manufacturing Sand From Rocks With B VSI 7611 in UAE stone stone crushers in kenya crushing jaw crusher manufacturing

Learn More

Feed sizes range from 40 mm to 350 mm, depending on the model. The main fields of application of jaw crushers are construction materials, mineralogy and

Learn More

Jaw crushers use compressive force to break down large materials into smaller, more manageable pieces. It has two crushing jaws (one is

Learn More

Jaw Crushers. Typical applications for jaw crushers are; Ore Mining. Rock Quarries. Sand and Gravel. Construction aggregates. Recycled concrete (concrete, asphalt, etc.) Industrial Applications (slag, anodes, metallurgy, chemical industries etc.) ROC Jaw Crusher. Roc Impact jaw crushers are widely used in mines and quarries around the

Learn More

Jaw crushers are heavy-duty machines and hence must be robustly constructed. The main frame is often made from cast iron or steel, connected with tie-bolts.

Learn More

Kleemann introduces new jaw crusher. company Kleemann has announced the launch of a new mobile jaw crusher - the Mobicat MC 110 (i) EvO2. The company says the new machine is designed with construction and demolition applications in mind and has a medium- to upper-range hourly output of up to 400t/h.

Learn More

construction of jaw crusher America Corp.'s Mobile Jaw Crusher. Sep 28, · America Corp. announces the introduction of the BR580JG-1 Mobile Jaw Crusher. With a newly designed vibrating grizzly feeder and an all-hydraulic drive system the new crusher is suitable for highway construction, quarry and demolition and excavation

Learn More

Jaw crushers are used in mines and quarries as primary crushers. A jaw crusher uses compressive force (mechanical pressure) for breaking of particles. Above

Learn More

Jaw crushers are generally defined by their opening size. For example, a 900x650 mm crusher refers to a crusher with an inlet measuring 900 mm by 650 mm. The main parts and main technical parameters of a jaw crusher are presented below. 1. Feed Chute 2. Drive Flywheel 3. V-belts 4. Electric motor 5. Motor Stand 6. Settings and Damping Group 7.

Learn More

Cone crushers and jaw crushers both work by compression, reducing materials by squeezing them until they break apart. The benefit that cone crushers offer over jaw crushers is their ability to output a more cubical product similar to impact crushers. Cone crushers have traditionally been used as secondary and sometimes tertiary crushing stations.

Learn More

AGICO jaw crusher series covers several models with capacities ranging from 1 ~ 3 tph to 500 ~ 1000 tph. There is always a model that could satisfy your production needs. Please notify that the PE series is for coarse crushing, and the PEX series is for fine crushing. Large and medium jaw crushers are one of our key products.

Learn More

All in all, thyssenkrupp’s jaw crushers are convincing due to their rugged and reliable design with high capacities, low wear and tear and high ease of maintenance. The advantages can be summarized as follows: Crushing of hard rock such as granite, basalt and ores. High capacity due to enhanced kinematics of the swing jaw.

Learn More

7/6 · Pe Jaw Crusher Jaw Crusher Construction News Products Apr 21 pepex jaw crusher series is usually called as jaw crusher and is a crushing appliance that was produced relatively early and it is generally regarded as the primary breaker and is applied to

Learn More

Working Principle of a Jaw Crusher. A jaw crusher mainly works on the principle of reciprocating motion exhibited by the moveable jaw of the jaw crusher. The repeated movement of the jaws

Learn More

Construction Jaw Crusher - karishmasteel.com. 20' X 30' Jaw Crusher. jaw crushers are the workhorse of the crushing industry for mining, construction, and demolition recycling. mt. baker mining and metals' jaw crushers are industrial grade, continuous duty machines. they take large pieces of rock, ore, concrete, or other materials, and crush

Learn More

3/29 · Jaw crusher is an earlier crushing equipment.Because of its simple structure, sturdiness, reliable work, easy maintenance and repair, and relatively low production and

Learn More

2/18 · A jaw crusher essentially crushes large rocks to a more usable size. They’re typically the first-line machinery used in the material reduction for several applications. This includes

Learn More